First Class Info About How To Reduce Defects

Reducing product defects needs to come from within the company or organization that is creating the product.

How to reduce defects. Finally, resist any impulse to forgo the carrot in favor of the. It should be holistic so that you don’t have to focus on only defect prevention as part of the tqm equation. The important thing is to start measuring the defect density and graph it over time.

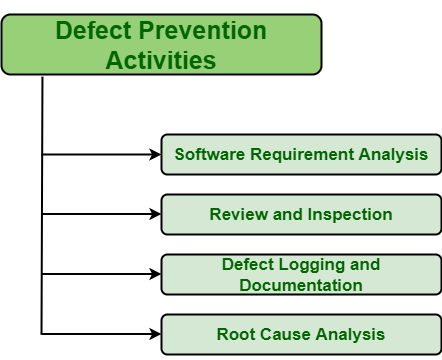

(a) continuous integration (b) make deployments to test and production environments trivial (c) an automated regression and. Avoiding defects in products also includes using quality materials and ingredients and having skilled workers throughout the production process. The analysis should lead to implementing changes in processes that help prevent defects and ensure their early detection.

Six sigma methods to reduce defects research. For example, a bottle of prescription drugs may become contaminated at a. You have to divide the defects by the sample size.

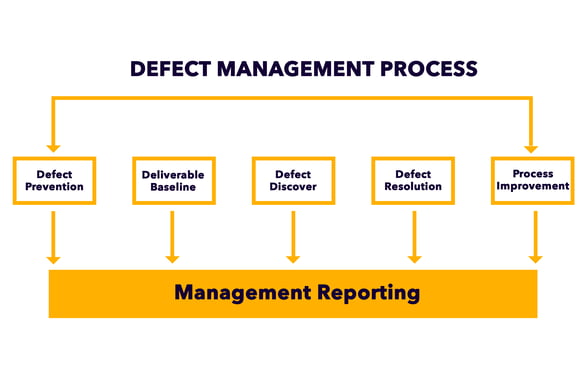

That solution should seem too easy, and, in fact, it is. Identify the process your team is following and find an alternative that might decrease the production defects. The definition of a defect is an imperfection or lacking that causes the person or thing with the defect to fall short of perfection.

Establish a golden sample to set quality expectations. In the example above, you have to divide 3 by 150 and the quotient is 0.02; Early defect detection helps early fixes.

Reducing the defects to improve the quality: How to reduce product defects. You must have a systematic approach.